We added two new

rotary draw benders, a 6” Coast Wallace and a Pines #6, to our current inventory of equipment.

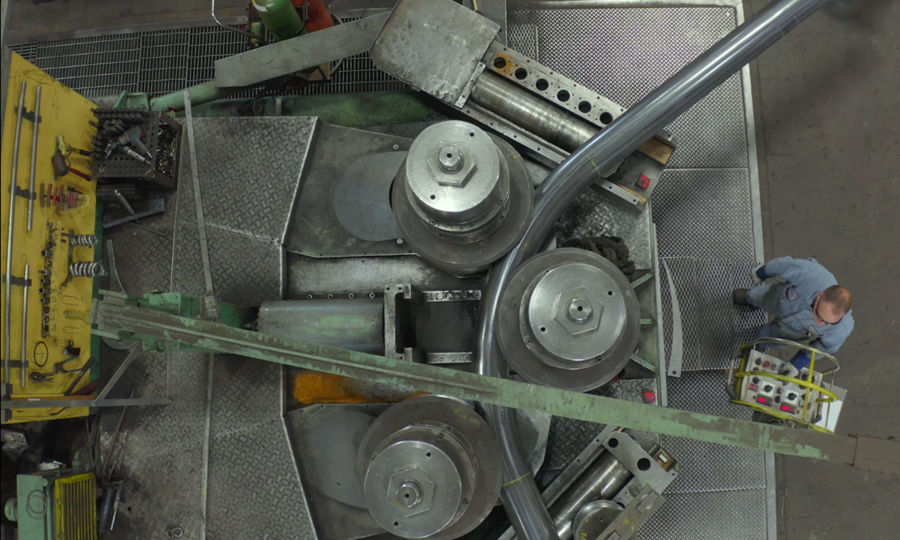

Rotary draw, or compression bending occurs when material is bent by rotating it around a bend die (and typically pulled or pushed over mandrel rod). A bend die is formed to fit a specific material size/type and at a specific diameter to fit the bend requirements. The material to be bent is clamped to the bend die and then is drawn, or pulled, around the bend die until the desired degree of bend is met. This method produces clean, tight radii bends and is mainly used by manufacturers or industrial companies. The 6” Coast is a long machine with a carriage assist and overhead clamp. The machine has the capacity to bend up to 6” pipe down to an 18” CLR. The machine has tooling allowing it to bend 2-1/2”, 3”,4”, 5” and 6” pipe to numerous radii. [caption id="attachment_976" align="aligncenter" width="1632"]

6" Coast Wallace Rotary Draw Bending Machine[/caption] [caption id="attachment_977" align="aligncenter" width="1632"]

Tooling for 6" Coast Wallace Rotary Draw Bending Machine[/caption] The Pines #6 is a long machine with a customized back boost. This machine has the capacity to bend up to 6” pipe (and has the ability to bend thin wall material). In addition to round materials, this machine has the capacity to mandrel bend square and rectangular tubing, in fact it is currently under power to bend TS 12” x 4” x 5/16” wall the easy way to a 24” CLR. We plan to fully tool these pieces of equipment allowing us to offer countless new radii options for our customers growing needs. The recent changes have greatly improved moral in our shop, increased our efficiencies, and decreased lead times in certain areas of the shop.