Scheduled to open its doors in 2025, the Morgan Center for Research and Innovation promises to redefine cutting-edge research in the fields of science and technology. This monumental 17-story facility is a testament to advanced architectural design and engineering, providing dedicated spaces for wet labs, genome sequencing, core facilities, mechanical infrastructure, and much more. The Morgan Center is poised to become a hub for groundbreaking discoveries, further cementing its place as a leader in the research community.

Architectural and Engineering Marvel

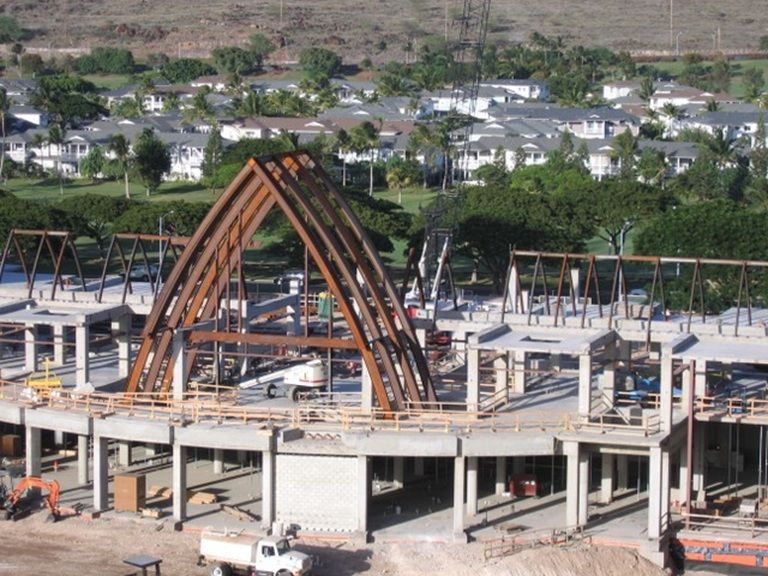

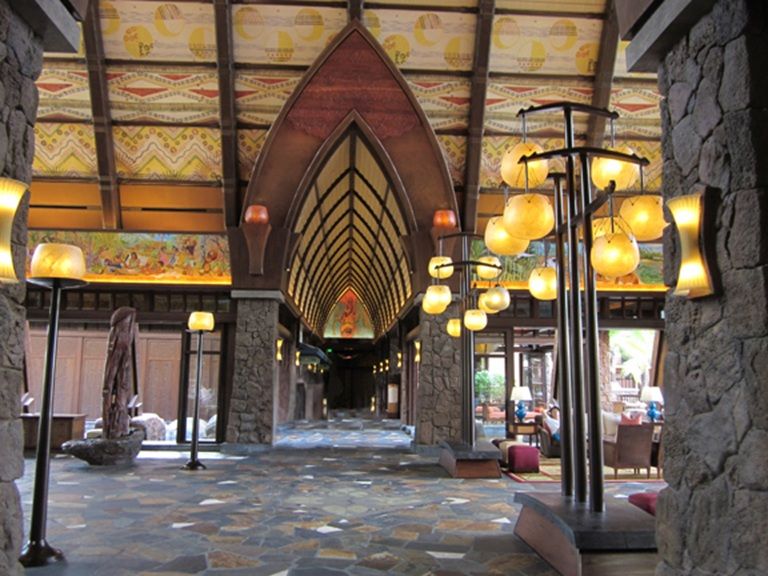

What sets the Morgan Center apart is not just its focus on innovation but also its state-of-the-art construction. The building integrates an impressive array of materials and design elements to meet the needs of modern research while embracing sustainable and forward-thinking practices. One of the key highlights of the project has been the inclusion of custom steel bending by Albina Co., Inc., showcasing the precision and expertise required for such a project.

Albina’s Contribution: Steel Bending Excellence

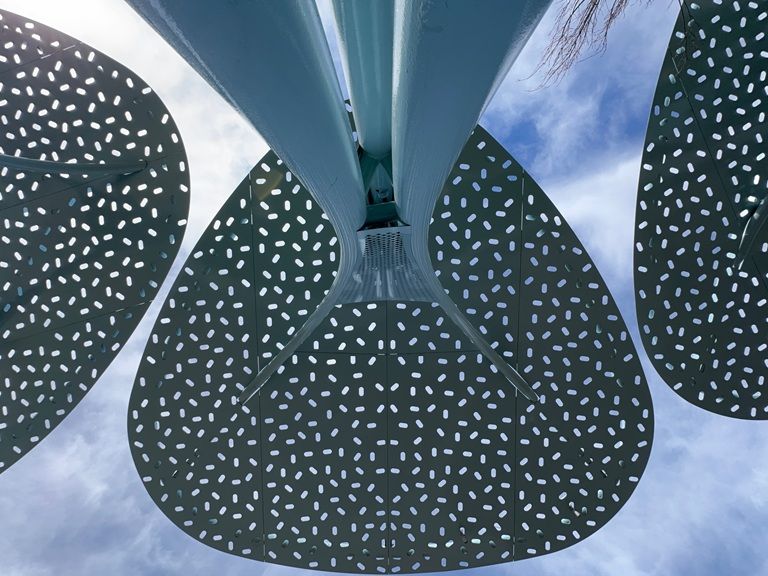

Albina Co., Inc. played a pivotal role in bringing the Morgan Center’s design to life. We supplied over 94 pieces (155,000 lbs) of 8" X 8" X .500" WALL A500 GR C structural steel, bent and cut to various dimensions and configurations. These materials form integral components of the building, including its windscreen steel, which has already been installed at the top levels.

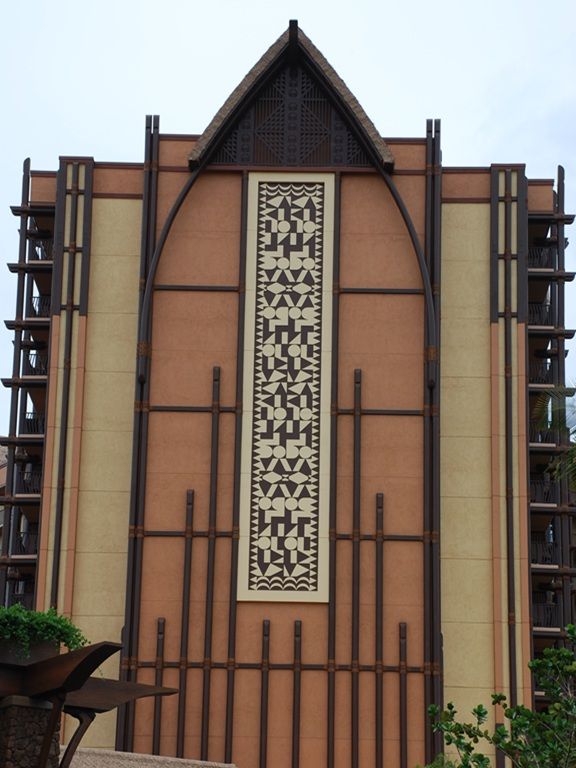

The windscreen installation marks a critical milestone in the construction process, adding a functional and aesthetic element to the building’s design. These components not only enhance the structure’s visual appeal but also provide structural reinforcement, showcasing Albina’s ability to deliver complex, high-quality steelwork for large-scale projects. Albina’s work doesn’t stop at the top. A separate section of the Morgan Center, located closer to the lower levels, will feature ribbon steel also provided by Albina. This bent steel will add another layer of visual and structural sophistication, tying together the building’s design elements from top to bottom.

The inclusion of these custom steel designs emphasizes the Morgan Center’s commitment to blending functionality, durability, and artistry in its construction. Albina’s expertise in steel bending has enabled the project to achieve its ambitious architectural vision.

Learn More

To stay updated on the Morgan Center’s construction progress and its anticipated opening, visit the Facilities Department’s Construction Page.

Albina Co., Inc.’s contribution to the Morgan Center highlights the critical role that precision steel bending and fabrication play in modern architecture. By enabling projects like the Morgan Center, Albina continues to set the bar for quality and innovation in construction.