At Albina Co., Inc., we are proud to have played a key role in the construction of the newly installed videoboard at Folsom Field, home to the University of Colorado Buffaloes. The massive videoboard debuted in the 2024 season opener and is over five times the size of its predecessor, measuring 130 feet wide and 36 feet high. The project includes a significant steel infrastructure to support the board, a critical element in maintaining its strength and durability over time.

For this project, our team was tasked with bending several large structural tubes to exacting specifications, ensuring the steel framework would hold this state-of-the-art screen securely. Here's a closer look at the steel bending work we completed:

Steel Bending for Folsom Field

For the videoboard's frame, we bent a variety of A500 Grade C structural tubes, known for their high strength and resilience. These tubes were bent "the hard way"—along their stronger axis—to achieve precise radii needed for the structural support.

- TS 12" x 8" x .500" Wall A500 Grade C

15 pieces bent the hard way to a 256’-5” radius. - TS 12" x 8" x .313" Wall A500 Grade C

10 pieces bent the hard way to a 256’-5” radius. - TS 8" x 8" x .313" Wall A500 Grade C

25 pieces bent the hard way to a 262’-0” radius.

Precision Bending for Structural Integrity

Bending the steel "the hard way" is a critical process that ensures the strength and longevity of the framework. In this case, it was especially important due to the videoboard's large size and the need for exacting precision to meet both design and load-bearing requirements. With radii of 256’-5” and 262’-0”, the structural elements had to fit seamlessly into the overall design.

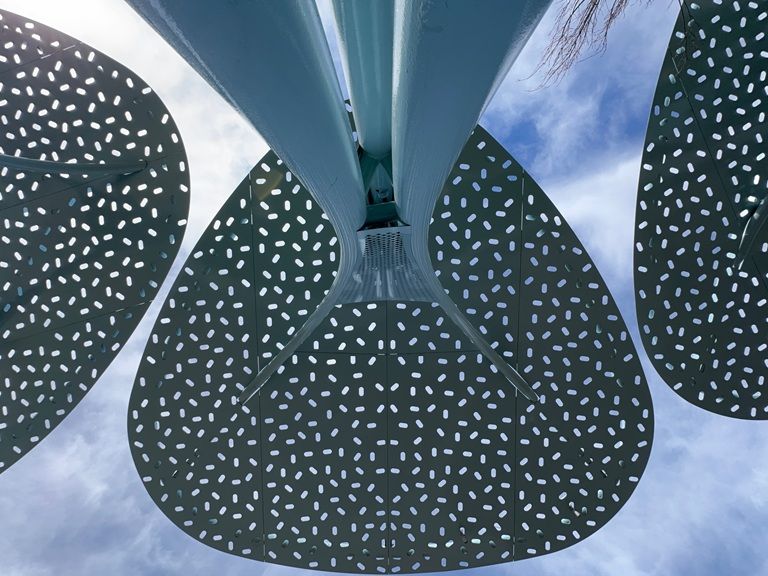

The bulk of this $15 million project is dedicated to the steel infrastructure, with four large columns running from the ground to the bottom of the videoboard, providing crucial support. The precision bending we provided ensures that the board will stand strong, even under the weight of the enormous display.

Why Choose Us for Your Steel Bending Needs?

We pride ourselves on delivering top-tier steel bending solutions that meet the most stringent requirements. Whether it's supporting a massive videoboard or crafting components for complex architectural projects, our precision bending services ensure that the job is done right the first time, every time.

The new videoboard at Folsom Field is set to transform the fan experience for Colorado Buffaloes football games, providing an immersive, high-definition display that is five times larger than the previous screen. Behind the scenes, our precision steel bending work ensures that this massive structure will stand the test of time, enhancing the atmosphere at Folsom Field for years to come.

We're proud to have contributed to this exciting new addition to the stadium, and we look forward to continuing to help bring ambitious projects like this to life.

Photo Credit: @_Kate Sands