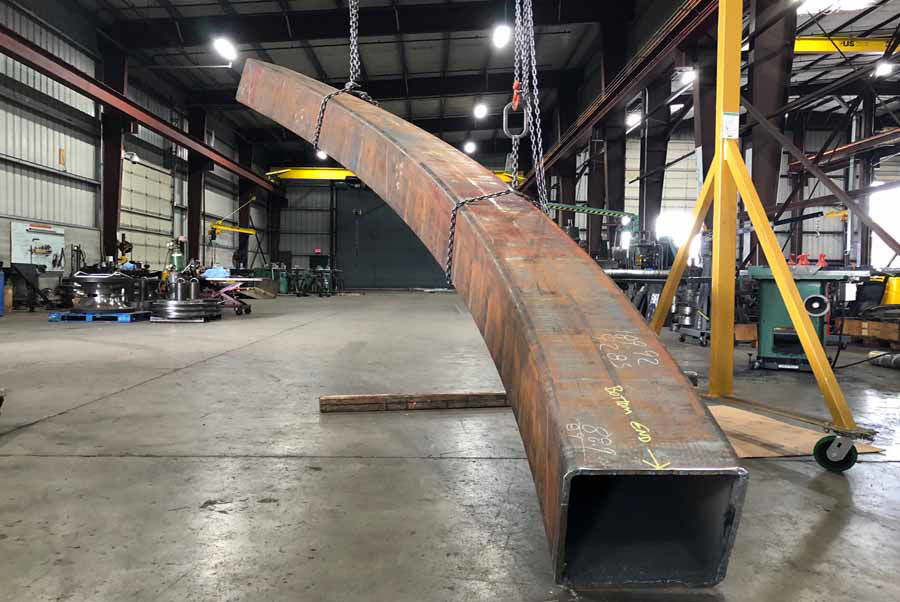

Albina Co., Inc., located outside Portland, Oregon, has been providing customers with innovative, quality curved steel services and products since 1939. A family owned and operated, third generation business, run by Brian Smith, specializes in structural steel, tube and pipe bending, plate rolling and fabrication. Albina produces virtually any metal component that needs to bend or curve without the use of pre-formed fittings. Albina has provided curved steel for many high-profile buildings, stadiums and structures in the United States and Canada. Albina was the steel bender of choice on the recently completed Amazon Spheres in Seattle,Washington.

Albina is an industry leader in research and development and in 2018, purchased an MCP30 by Davi, the first type of bending machine in the United States with a “iRoll” smart camera system, allowing operators to view the part being bent compared to a radius template on the control screen. The machine has the ability to “learn and remember” how different materials bend, where the rolls need to be positioned, and how much spring back is associated with a bend / material.

Albina also purchased a Bend-Tech Dragon A400 Plasma Cutter, a commercial grade CNC tube cutting ,engraving, and marking machine with the world’s most powerful CAD/CAM software. Other new equipment included new welders, jib cranes, induction heating coils, an electric forklift and 40 sets of tooling.

Albina was an instrumental player in the development of the first ever Design Guide of its kind in the United States offering information on the fabrication, design and detailing of curved members. Design Guide 33 “Curved Member Design” was released in October 2018 by the AISC Bender/Roller committee and is an invaluable resource for the industry!

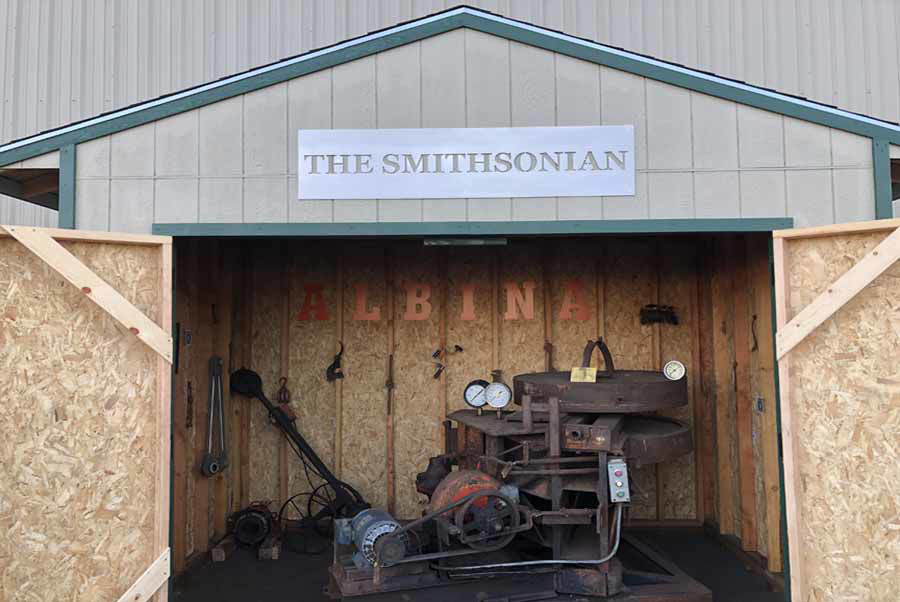

Albina not only has one of the newest, most technologically advanced machines on the market, Albina also has one of the oldest, custom made bending machines ever created! In honor of the 80th Anniversary, Albina created a museum on site, called “The Smith-sonian”, honoring the family name and housing one of the first ever pieces of equipment that Albina owned and used to bend materials. Brian’s grandfather built the“Model-T” bending machine in the early 1940’s utilizing the transmission and differential from a “Model-T” Ford. This machine was used until the 1990’s to bend various materials such as pipe, tube, and square and rectangular hollow structural steel. “The Smith-sonian” is ready for visitors. Cheers to 80 Years!