We recently spiral rolled 1/2" and 1" plate for a custom spiral staircase in a multi-million dollar luxury home on Green Street in San Francisco, California. We provided the rolled plate for the staircase and then flat plane rolled the plate for the landings. The tightest radius was a 29.75” center line radius.

Blog posts tagged with 'structural steel bending profiles'

The downtown BART Berkeley (Bay Area Rapid Transit) station is conveniently located close to the University of California campus and to many shops, restaurants, theaters and other attractions, and has valet bike parking. Albina has been involved in several BART projects over the years and this is just the most recent one. We rolled various sizes of tube steel and angle including: Tube Steel 6" X 6" X .375" WALL A500 GR B- all bent to a 32 ft radius. Tube Steel 6" X 5" X .250" WALL A500 GR B- all bent the hard way to a 22 ft radius. All parts provided by Albina rolled, trimmed to length and notched for fabrication. Tube Steel 12" X 8" X .500" WALL A500 GR B. Bent by Albina the hard way to a 41 ft radius. Tube Steel 12" X 6" X .375" WALL A500 GR B. Bent by Albina the easy way to a 109 ft radius. Tube Steel 10" X 6" X .500" WALL A500 GR B. Bent by Albina the easy way to a 110 ft radius. 2½" X 2½" X ¼" ANGLE T316 S/S. Bent by Albina with the leg out to a 21 ft radius. Albina produces architecturally designed pedestrian bridges and walk-ways as well as motor vehicle and mass transportation bridges and support systems erected at transportation stations, universities, museums, large businesses, state park, etc.Here are some pictures. Check back for more pictures!

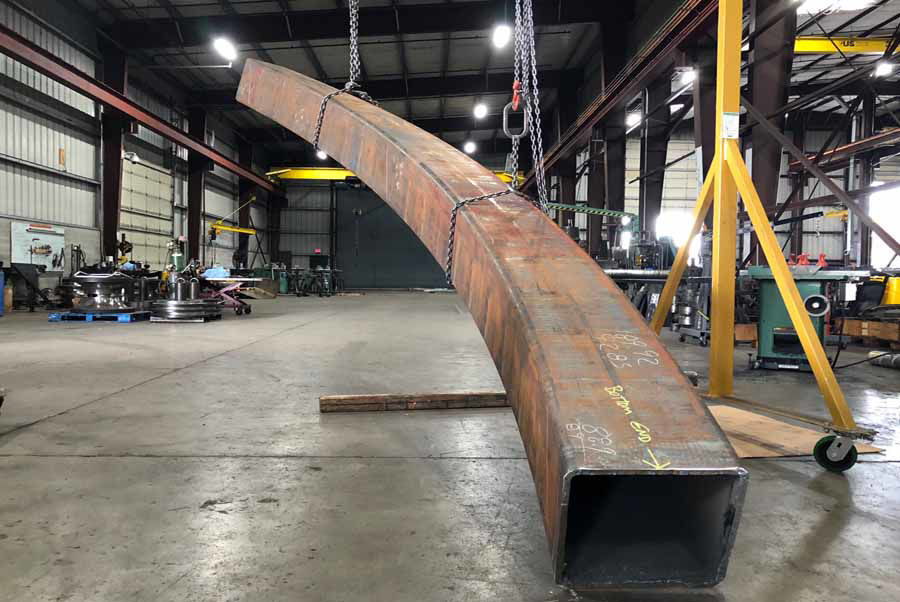

Albina recently used our induction heating process to spiral bend Tube Steel 16" X 16" X .625" WALL A500 GR B bent down to a an 18 foot radius for the new American Airlines headquarters in Fort Worth, Texas. The 1.7 million-square-foot complex, dubbed the “Trinity complex,” consists of constructing four seven-story buildings. It will cost at least $300 million to build and will house over 6,500 employees. There are 10 tower cranes on the project and there will be more than 1,000 construction workers on-site during the peak. It is scheduled to open during the second half of 2019. Including the 16" square, we have produced another set of spirals and have one in the queue. The one in the queue is Tube Steel 14" x 6" x .625" wall REALLY tight, exposed and bent to a 5'-6" radius on a 45° pitch. We already made a mock up for the job and all parties loved it. These are the type of bends that ONLY Albina can do! This is a really amazing project! Stay tuned for more pictures.

We recently completed a very difficult job in which we bent 3" OD X .065" WALL T304 Stainless Steel POLISHED, 2½" OD X .065" WALL T304 Stainless Steel POLISHED, and 1/2" OD X .065" WALL T304 Stainless Steel Polished for a manufacturing customer. The really tight bends in the picture below are elbows (butt-weld fittings) that are purchased off the shelf at a pipe supply house. The bends we did are the larger radii bends. Albina is a reliable vendor when it comes to producing bent parts for manufacturing applications. When applicable, we can provide same day and/or shutdown services which is a huge plus for customers that rely on equipment running 24 hours a day. Albina is also qualified to process NQA-1 work for certified NQA-1 shops.

We partnered with Architectural Elements, a specialty metals fabrication shop in Bellingham, Washington to create this wind sculpture for the city of Oak Harbor. Albina bent 3½" SCH40 A53B ERW WHEELED- 10 lengths x 42 feet for the project. The sculpture was designed by Architectural Elements design engineer, Kyle Thomas and the photos below are © 2018 by Melissa Marteny.

We currently have a job in progress that involves bending tube steel and doing some very complex end coping on the material for some custom skylights at the Philadelphia Museum of Art. The coped ends are VERY complex. Every machine shop we contacted to cope these ends and slot these ends all declined. With all of our technical expertise, we figured out how to do the ends in-house. It is the most complex end details we have ever worked with. Albina is bending, trimming, slotting and miter cutting 150 pieces of TS 5" X 3" X .375" WALL A500 GR B and TS 4" X 3" X .375" WALL A500 GR B per drawings down to a 4'8" radius. Our customer will do the remainder of the fabrication. Stay tuned for more pictures as we near completion of the job!

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2010

- 2009

- 2008

- 2007